Some friends will wonder why inorganic coating should be thickened after thickening, which is completely different from other materials, so only to understand the meaning of the subsequent operation can be better, then what is the reason for the thickening? The following powder coating powder manufacturer for you to bring solutions.

Thickening after inorganic coating:

1. The amount of wetting agent is small, or the quality is not very good, the actual wetting effect is not very good;

2. the proportion of particle material with low density is too large;

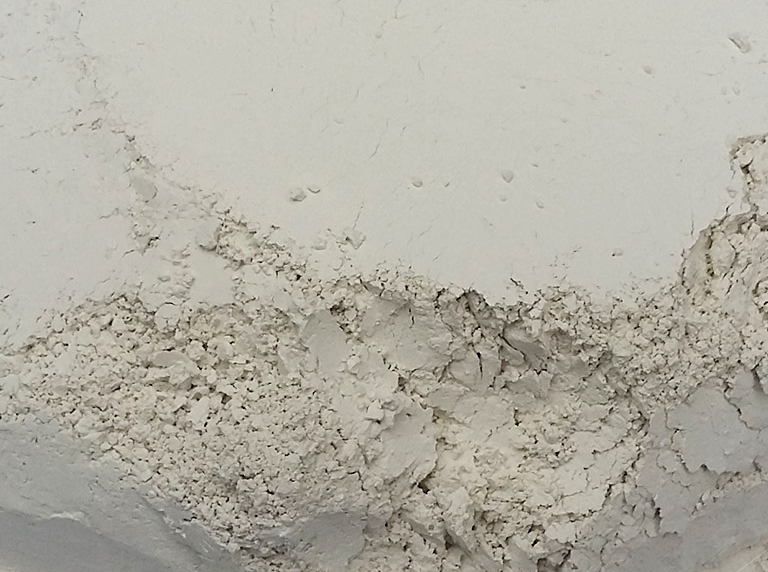

3. the fiber is encapsulated by moisturizing emulsion without mixing, and this kind of problem makes the paint surface in the bucket produce cracks;

4. the sodium ion of moisturizing emulsion is not very stable;

5. viscosifiers themselves or cooperate with each other. Thickening after viscosity lag caused by thickening; the thickening caused by the adhesion of color paste and filling material is generally caused by the insufficient use of thickening agent in the production process of architectural coatings; the improper collocation of thickener and thickener occurs in the management system of the combination of low-ion concentration hydrophilic thickener and alkali solubilizer or hydrophilic modified material alkali solubilizer.

Definition: The condition that the viscosity of architectural coating changes continuously in the storage link after it is made. Classification of thickening after construction coating:

A. Predictable thickening after analysis caused by viscosity equalization;

b. Unpredictable thickening after analysis caused by management system reliability.

Inorganic coatings after thickening solution:

1. The whitening agent is likely to add too much, preferably not more than 200 grams per ton;

2. decentralization time is likely to be insufficient;

3. light calcium is likely to be too much, one ton does not have to exceed 150KG, because light calcium oil absorption flow is large, and sodium ions are unstable. For a long time, the moisture and moisturizing emulsion are absorbed into the gap of light calcium particles, resulting in thickening.

4. Hydroxyethyl methyl cellulose to thoroughly participate in the dispersion, or methyl cellulose aqueous solution is not completely melted in the system, may also cause after thickening;

5. the most important thing is that the viscosifier is likely to choose unscientific, you are likely to choose only cheap alkali soluble swelling type. This kind of viscosifier and weak alkaline paint reflect, the longer the time, the greater the viscosity. Can add some protonated viscosifier and alkali soluble viscosifier compound application.

Inorganic coating viscosity has a strong thickening property.

Good compressibility.

PH integration coverage is wide.

Good reliability and other advantages. However, because the sodium bentonite is an inorganic powder with good light absorption, it can significantly reduce the gloss of the coating surface and has the effect of a similar extinction agent.